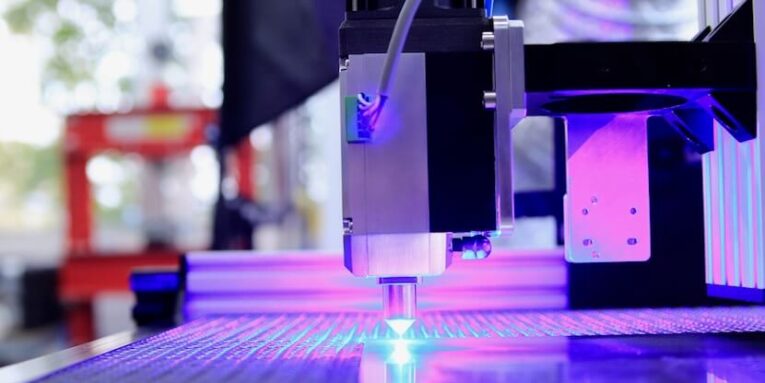

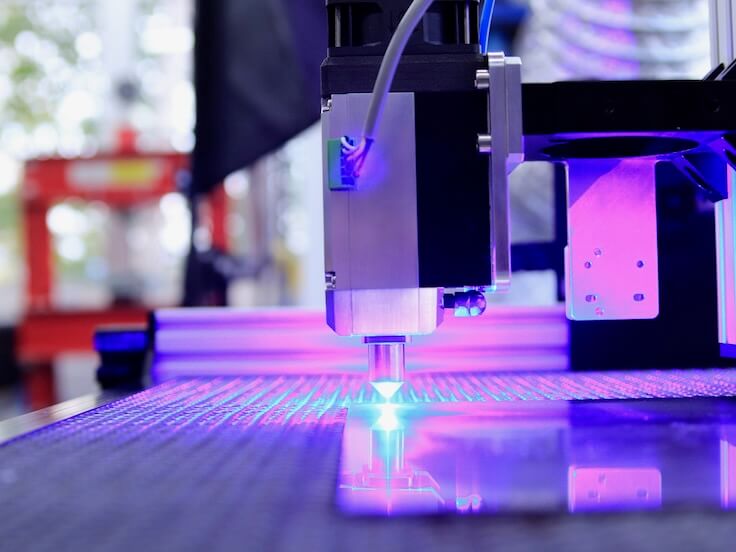

Laser technology has completely reshaped how we design, label, and fabricate materials. From precision-cut signage to intricate branding on metal tools, lasers make it possible to achieve stunning detail with remarkable consistency. Still, not every laser technique works the same way. Knowing how engraving, etching, and cutting differ is important for anyone aiming for a clean, professional finish.

For those seeking top-tier results through laser engraving in Melbourne, this knowledge goes a long way. Each process serves its own purpose, depending on how deep the mark needs to be, what material you are working with, and the intended outcome.

The Precision and Permanence of Laser Engraving

Laser engraving is the heavy-duty option of the trio. It works by vaporising layers of material, carving deep, permanent impressions that can be felt as well as seen. This makes it a go-to choice for metals, glass, wood, leather, plastics, and anything that needs durability.

What sets engraving apart is depth. While other marking methods might skim the surface, engraving digs in, producing markings that stand the test of time. That is why it’s often used for serial numbers, barcodes on machinery, and personalised items like awards or keepsakes.

In manufacturing and design circles, engraving holds real value. Its reliability and clarity make it indispensable in industries ranging from engineering and product design to signage and home decor. When consistency and endurance matter, engraving delivers.

Laser Etching for Detailed Surface Marking

Etching is often confused with engraving, but the difference lies in how much material is removed. Instead of cutting deep, etching alters only the surface, either by melting, oxidising, or discolouring it. The result is a crisp, detailed mark that does not compromise the integrity of the material beneath.

This method shines when time and aesthetics are priorities. It is faster, gentler on materials, and ideal for delicate branding work such as logos, serial codes, and decorative touches on anodised aluminium, coated metals, or glass. Because the laser operates at a shallower depth, it also puts less strain on the machine, making it cost-effective for bulk runs or repeat projects.

While etching is not as long-lasting as engraving, it is perfectly suited for products where the design’s appearance matters more than its resilience.

The Precision and Power Behind Laser Cutting

Laser cutting is a different beast altogether. Instead of leaving a mark, this process slices straight through the material using concentrated, high-energy beams. This results in clean edges, smooth finishes, and no need for post-cut sanding or polishing. This technique has become a cornerstone in industries like signage, fashion, architecture, and prototyping.

It is also quite versatile, capable of cutting through acrylic, wood, MDF, paper, fabric, and even certain plastics. With the right setup, industrial lasers can also handle metals with remarkable accuracy. However, successful cutting requires more than raw power. Each material reacts differently to heat and beam frequency, so knowing how to fine-tune the settings is key.

Choosing the Right Laser Process for Your Project

Choosing between engraving, etching, and cutting comes down to the type of material, how permanent the result needs to be, and what purpose the finished piece will serve. A stainless-steel tool needing a permanent mark will benefit most from engraving, while a delicate glass trophy may call for the softer touch of etching.

Meanwhile, if you are crafting signage or shaping parts for a prototype, laser cutting will deliver the clean precision you need. Partnering with a knowledgeable laser specialist can help.

Final Thoughts

Knowing the difference between these three laser processes helps you make smarter choices for both design and functionality. Whether you want to engrave a logo that lasts for decades, etch a fine pattern onto a glass panel, or cut intricate shapes from acrylic, knowing what each method can do puts you in control of the outcome.

Professional providers skilled in laser engraving have the tools and experience to bring these techniques together seamlessly. By combining technical expertise with creative precision, they help transform simple materials into pieces that look refined, perform well, and last.

People also read this: 10 Improvements to Make Financial Planning Easier for Your Business