The harmonic balancer is a critical component of any internal combustion engine, designed to reduce vibrations from the crankshaft and ensure smooth operation. Over time, the harmonic balancer can wear out, develop cracks, or become loose, leading to engine noise, poor performance, or even damage to the crankshaft. For both DIY enthusiasts and professional mechanics, understanding what a harmonic balancer puller is and how to use it is essential for effective engine maintenance. With the proper tools, including a balancer puller set, removing and replacing the harmonic balancer can be a safe and manageable task.

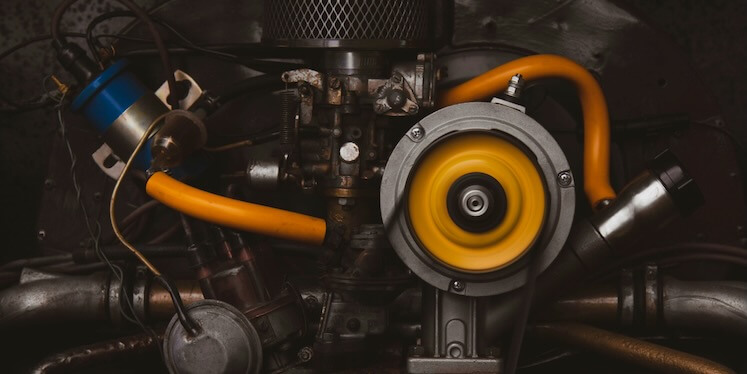

A harmonic balancer, also known as a crankshaft damper or vibration damper, is typically mounted on the front of the engine’s crankshaft. It consists of a hub, an outer ring, and a rubber or elastomer layer that absorbs torsional vibrations produced by the engine. Without a properly functioning balancer, these vibrations can lead to premature wear on engine components, crankshaft damage, or failure of accessories such as belts and pulleys. Recognizing signs of a failing balancer—such as unusual engine vibrations, squealing belts, or visible cracks—is the first step toward timely maintenance and repair.

Before attempting to remove a harmonic balancer, it’s important to prepare your workspace and gather the right tools. A harmonic balancer puller is specifically designed to safely extract the balancer from the crankshaft without causing damage to the pulley or engine components. These tools often come as part of a balancer puller set, which may include different adapters to fit various engines. Having a quality puller ensures that the removal process is controlled and minimizes the risk of injury or component damage. Along with the puller, basic automotive tools such as wrenches, sockets, and screwdrivers, as well as safety equipment like gloves and eye protection, are necessary for a successful repair.

The process of crankshaft pulley removal begins by disconnecting the battery and ensuring the vehicle is on a flat, stable surface. Removing any components that obstruct access to the harmonic balancer, such as fan assemblies, belts, or covers, allows for a clear path to the crankshaft. Once you have access, the harmonic balancer puller can be attached to the balancer. The puller typically has arms or bolts that grip the balancer securely, and a center bolt that, when turned, applies controlled force to pull the balancer off the crankshaft. Using gradual, even pressure is essential; attempting to pry the balancer off without the proper tool can damage the crankshaft, the balancer itself, or surrounding engine components.

DIY harmonic balancer replacement is a process that requires attention to detail and careful handling. After removing the old balancer, inspect it for wear, cracks, or deterioration in the rubber layer. The crankshaft should also be inspected for damage or scoring that could prevent proper installation of the new balancer. Cleaning the crankshaft surface and applying a small amount of lubricant to the hub can help the new harmonic balancer slide on more easily during installation. Proper alignment is crucial; the balancer must sit flush against the crankshaft with any keyways aligned correctly. Misalignment can lead to engine vibrations, premature wear, or failure of connected components.

When installing the new harmonic balancer, it is often helpful to use a press or a suitable installation tool to ensure it goes on straight and evenly. Some balancer puller sets include installation adapters, allowing the balancer to be pressed onto the crankshaft without damage. After installation, torque the crankshaft bolt to the manufacturer’s specifications and double-check alignment. Reinstall any components removed during the process, including belts and fan assemblies, and reconnect the battery. Starting the engine and observing for unusual noises or vibrations confirms that the repair was successful.

There are several practical tips to keep in mind when using a harmonic balancer puller. Always select the correct adapter for your engine to ensure a secure grip. Work slowly and evenly when applying pressure; rushing can lead to slippage or damage. Inspect both the balancer and crankshaft before and after removal for signs of wear. Using a balancer puller set ensures you have all the necessary components for safe and effective removal, and investing in quality tools pays off in reliability and ease of use.

One common mistake when attempting crankshaft pulley removal without the proper tool is relying on hammers or pry bars. This approach can deform the balancer, damage the crankshaft snout, or cause serious injury due to the force stored in the component. A harmonic balancer puller eliminates these risks by applying controlled, even pressure directly along the axis of the crankshaft. This is especially important for DIY mechanics who may not have the experience to compensate for uneven force or unexpected resistance.

Maintaining a harmonic balancer is also part of overall engine upkeep. Regularly inspecting for cracks, corrosion, or separation of the elastomer layer can prevent engine vibrations and associated damage. If the balancer shows any signs of failure, timely replacement using the proper tools can extend the life of the engine and related components. Coil spring maintenanceor other suspension-related work may sometimes be necessary in conjunction with engine service, as vibrations from a failing balancer can affect the overall driving experience.

For DIY enthusiasts, understanding how to use a harmonic balancer puller opens the door to more advanced engine repairs and maintenance. Not only does it reduce reliance on professional services, but it also builds confidence in working with complex automotive systems. Professional mechanics rely on these tools daily, and for good reason: a controlled, safe removal process prevents costly mistakes and ensures the longevity of engine components. By combining proper tool use with careful observation and adherence to manufacturer guidelines, both hobbyists and professionals can perform harmonic balancer replacement with confidence.

In conclusion, the harmonic balancer is a small but vital part of your vehicle’s engine, and knowing how to safely remove and install it is an important skill for any mechanic. A harmonic balancer puller, preferably as part of a balancer puller set, allows for controlled, precise removal and installation, reducing the risk of damage or injury. Whether you are performing DIY harmonic balancer replacement at home or as part of professional automotive work, understanding proper techniques for crankshaft pulley removal and installation ensures that your engine operates smoothly and reliably. Paying attention to detail, using the right tools, and following safety protocols will make harmonic balancer service a manageable and rewarding task.

People also read this: Simulate First, Cash In Later: How Smart Design Captures 45L, 25C, and 179D in 2025